Welcome to CLS Operational Excellence

Hello and Welcome. We are CLS Operational Excellence, a consulting and sorting firm composed by professionals with more than 20 years industrial experience. Our aim

Dedicated to analyse, evaluate and define the best strategy and tools to reach your Operational Excellence

We can efficiently found the best alternative to your project operational needs.

CLS Operational Excellence bring you a consulting and specialist team, ready to provide answers to your needs and increase, in this way, your market competitiveness.

That is the reason why we join you in your path through Excellence, we work with your team and in your plant to reach the desired goals.

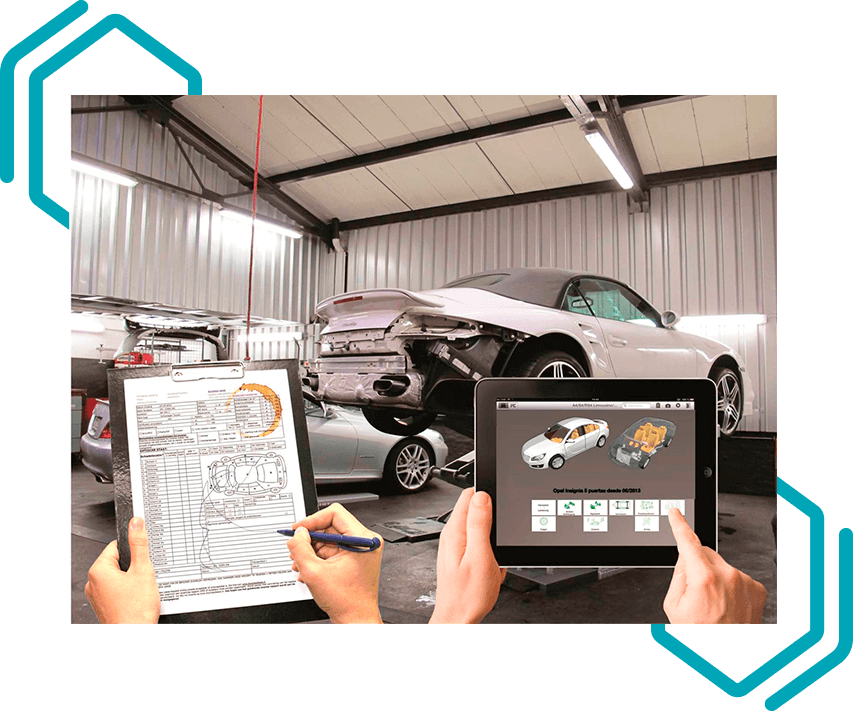

We also provide solutions in your needs for inspection, sorting and re-working activities.

Our philosophy is to provide you an overall service based on following principles

The Operational Excellence in a production plant, can be defined as the philosophy which adopt certain principles and tools in order to reach a sustainable continuous improvement.

GP12, Safe launch, CS1 y CS2, Incoming Inspection.

All these words, commonly used in automotive industry, are tools used to guarantee the quality of every produced and delivered product.

Dedicated to analyse, evaluate and define the best strategy and tools to reach your Operational Excellence.

The Operational Excellence in a production plant, can be defined as the philosophy which adopt certain principles and tools in order to reach a sustainable continuous improvement.

As in every Lean Manufacturing & six sigma processes, we will focus on detect and remove all waste and main variations in your processes.

As a sorting service, we provide you with an efficient inspector’s team, with different tools to assure the quality of the products you deliver to your customers.

Hello and Welcome. We are CLS Operational Excellence, a consulting and sorting firm composed by professionals with more than 20 years industrial experience. Our aim

CLS Operational Excellence® 2020

Provide to all small and medium Mexican’s production plants, with all necessary tools and skills, to achieve the Operational Excellence, at an accurate cost and provided by a first level profesional team.

Achieve a leadership position in consulting and sorting among small and medium Mexican’s production plants.